Professional Sheetrock Repair Fort Worth for Quick Fixes

Total Guide to Dependable and efficient Drywall Installation

Drywall installation is a critical element of any kind of building and construction or restoration task, requiring a meticulous approach to make certain both effectiveness and dependability. Comprehending the crucial devices and methods is paramount, along with acknowledging typical mistakes that can lead to poor outcomes. By methodically preparing the room and applying finest practices, one can attain a perfect finish that stands the test of time. It is essential to discover the nuances of each action in the process, as they jointly add to the general success of the drywall installation. What certain techniques can boost your approach?

Crucial Tools for Drywalling

When starting a drywall installment job, having the right devices is crucial for accomplishing a specialist finish. Crucial devices include a drywall blade, measuring tape, and a T-square, which are essential for exact dimensions and smooth cuts. A drywall lift is also very valuable, specifically for ceiling installments, permitting easier handling of hefty panels.

For attaching the drywall, a cordless drill and drywall screws are needed. The drill ought to be furnished with a drywall little bit to make sure effectiveness and precision. In addition, a key device is the drywall saw, which promotes reducing about various other barriers and electric outlets.

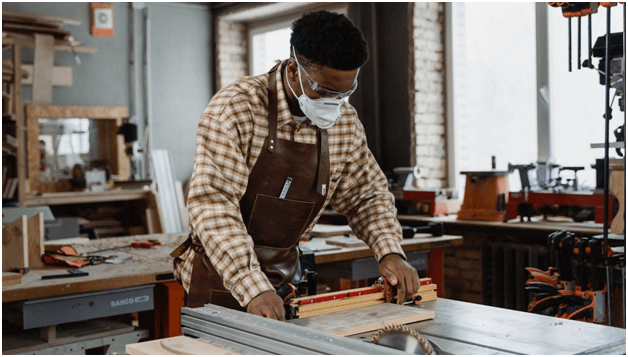

Furthermore, protective gear such as security glasses and a dust mask are necessary to guarantee personal safety throughout the setup process. Utilizing the right devices not just enhances the quality of the installation but additionally simplifies the process, making the project much more efficient total.

Preparing the Area

Following, evaluate the problem of the walls and ceilings. Fix any existing damages, such as holes, fractures, or peeling off paint, to make certain a smooth and also surface for drywall application. Additionally, check for electric outlets, plumbing lines, and HVAC ducts, noting their locations to stay clear of complications throughout installation.

It is likewise crucial to determine the room precisely, establishing the measurements of the ceilings and wall surfaces to calculate the proper quantity of drywall needed. Create a thorough plan that includes the design and alignment of the drywall panels.

Installation Methods

Reliable installation techniques are important for achieving a professional surface in drywall Learn More Here projects. Correct dimension and cutting of drywall sheets are basic actions. Constantly gauge the wall surface space precisely, enabling any kind of outlets or switches. Utilize an energy blade for tidy cuts, racking up the paper face and breaking the board along the racked up line.

When hanging drywall, begin with the top and job downward, ensuring that the lengthy side of the board is perpendicular to the framing. Safeguard the sheets with screws instead of nails, which give higher holding power and lower the danger of standing out. Location screws every 12 inches along the edges and every 16 inches in the area of the board.

For corners, use edge grains to accomplish sharp, tidy edges. When installing on ceilings, utilize a drywall lift or have a companion aid in holding the sheets in place (drywall installation). Preserve a space of about 1/4 inch over the flooring and ceiling to fit growth and contraction

Finishing Touches

Begin by using joint tape over the joints. This can be either paper or fiberglass mesh tape, with paper being preferred for its toughness. When the tape remains in location, it's time to apply the first layer of joint substance, additionally recognized as mud. Utilize a 10 to 12-inch taping blade to spread the substance equally over the taped seams, feathering the sides to blend with the surrounding drywall.

Enable the substance to dry thoroughly, commonly 1 day. After drying out, sand the surface lightly with fine-grit sandpaper to get rid of any blemishes. drywall repair. Repeat the mudding explanation and sanding procedure, usually a couple of layers, making sure each layer is flush and smooth with the drywall surface area

Usual Mistakes to Prevent

Several DIY lovers encounter risks during drywall setup that can endanger the outcomes. One usual mistake is stopping working to effectively gauge and cut drywall sheets. Unreliable cuts can result in gaps and unequal joints, making ending up much more labor-intensive. In addition, disregarding to surprise joints can produce powerlessness in the wall surface, resulting in potential drooping or breaking gradually.

An additional constant mistake is improper attachment. Making use of also few screws or nails can cause her response loose drywall, while overdriving fasteners can create the paper to tear, weakening the structure. It's vital to maintain consistent spacing, usually every 16 inches, and to make certain that bolts are flush with the surface.

Moreover, not attending to wetness issues prior to installation can result in mold growth and architectural damage. Constantly evaluate the atmosphere and use moisture-resistant drywall in high-humidity areas.

Final Thought

Efficient and reliable drywall installation needs precise interest to detail throughout the procedure. By making use of essential tools, preparing the area effectively, and adhering to ideal practices in setup methods, a flawless coating can be accomplished. In addition, cautious application of joint substance and tape throughout the finishing stage improves toughness and appearance. Avoiding typical mistakes further contributes to a professional result, highlighting the significance of precision and technique in successful drywall projects.

It is necessary to explore the subtleties of each action in the process, as they jointly contribute to the total success of the drywall installment.When getting started on a drywall installation project, having the right devices is essential for achieving a specialist coating.For attaching the drywall, a cordless drill and drywall screws are necessary.Effectively preparing the space is essential for an effective drywall installment.Reliable installation methods are vital for achieving an expert surface in drywall jobs.